GETECH 12-inch GMES System: Building a Solid Foundation for Intelligent Manufacturing, Leading the Digital New Journey of 12-inch Wafer Fabs (Part 2)

In response to the development trends and traditional system pain points of 12-inch wafer fabs, GETECH has launched a new generation 12-inch GMES system, comprehensively helping 12-inch wafer fabs achieve management upgrades and efficiency leaps. In the previous part, we detailed the system's full-process function coverage. This part will focus on architectural advantages, refined management, and intelligent capabilities, further interpreting its core value.

Architecture Foundation Built for 12-inch: High Availability and High Stability, Supporting Uninterrupted Production of Advanced Processes

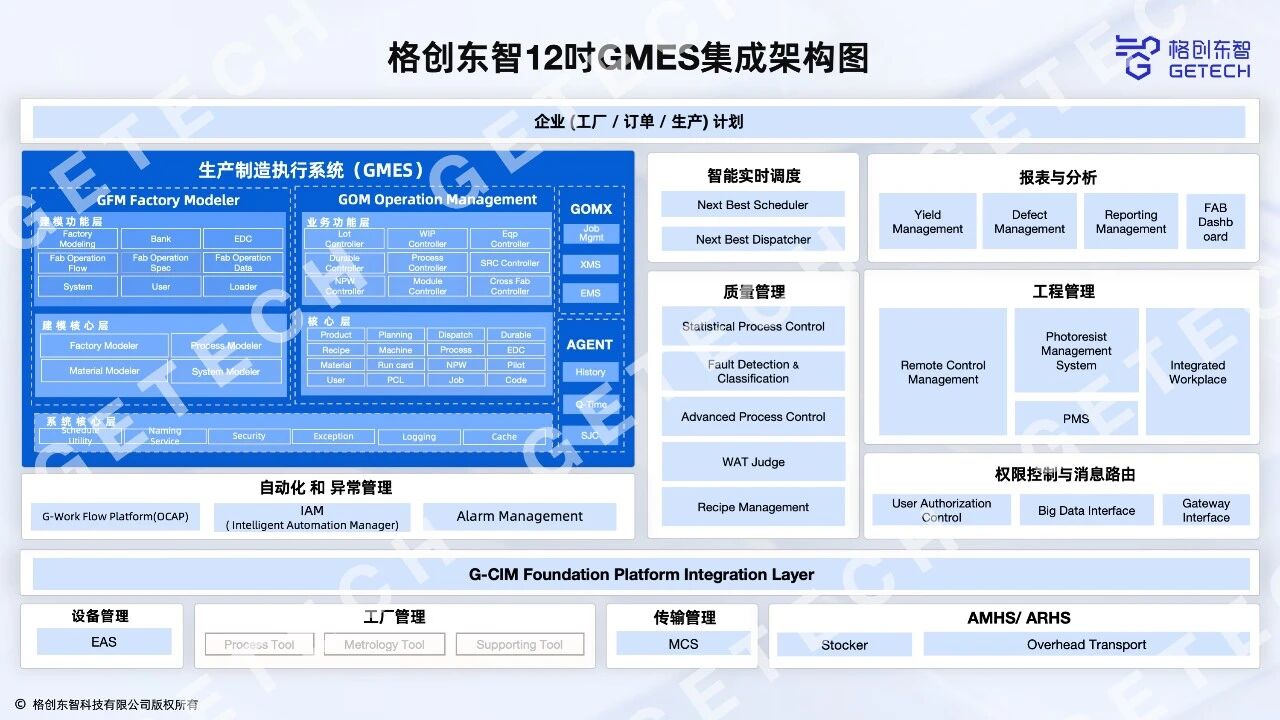

For the complex environment of 12-inch wafer fabs with thousands of equipment, tens of thousands of concurrent operations, and cross-factory collaboration, GETECH's GMES system adopts a mature microservices + message bus architecture, combined with HA high-reliability clusters, distributed caching, and object lock mechanisms, to build a highly available and highly stable digital foundation.

Designed for large-scale 12-inch Fabs: Through elastic scaling service clusters and database sharding strategies, supporting capacity expansion from tens of thousands of wafers per month smoothly, adapting to long-term development needs.

Fully Auto driven: Through the IAM intelligent automation management platform, with three engines of "AI + event flow + workflow", quickly configure fully automated requirements, helping "lights-out factory" construction.

Multi-system seamless integration: Based on the CIM basic integration platform, out-of-the-box integration with systems like EAP, SPC, FDC, breaking information silos, ensuring real-time information synchronization and efficient collaboration.

High availability, high reliability: Supporting multi-instance clusters, gray release, and rolling upgrades, ensuring system availability still reaches 99.999% during version evolution, avoiding upgrade shutdown risks.

150k-level pressure testing capability: Through 150k-level transaction concurrent pressure testing, maintaining key transaction average response time far below 1 second under complex transaction combinations, dealing with large-scale engineering experiments and overlapping mass production scenarios.

For CIOs and IT heads, this means that in the next 5-10 years of process upgrades and capacity expansion, there is no need to frequently refactor due to "the system can't handle it".

Refined and Closed-Loop Management for Processes

The competition of 12-inch wafer fabs is essentially a competition of "detail" management capabilities. GETECH's GMES system, with refined management as the core, builds a closed-loop system covering modeling and mass production stages, adapting to the stringent requirements of advanced processes for details.

Rapid Implementation of New Products/New Processes

Provides one-stop configuration management for basic data, factory resources, and process flows.

Through the Smart Loader rapid modeling tool, supports process, manufacturing, and development engineers collaborative modeling, shortening the introduction cycle of new products and new processes.

Achieves precise control of process versions and dynamic adjustment at the Lot level, ensuring process consistency and full traceability.

Refined Control in Mass Production Stage

Comprehensive data security: Triple permission control, integrated with OA system to achieve unified account management and hierarchical authorization.

NPW management: Achieves automated inventory management, dynamic stocking, and intelligent reuse of wafers in process, through three-stage NPW Flow and line-side warehouse level control, reducing material waste and FOUP occupancy.

Experimental batch management (SRC): Using Split/Return/Merge as the framework, supports configuring Recipe, equipment, EDC and other parameters per wafer, meeting complex experimental needs, and linking with MES, FDC, SPC to achieve closed-loop analysis of experiments.

Exception handling closed-loop (RRC+AMS): When process abnormalities occur, through RRC multi-path Rework Flow, various wafers are processed according to different strategies, and combined with AMS alerts and workflow, achieving transparent management of the whole process from exception discovery, responsible person receipt, processing execution to closure.

These refined controls work together to help 12-inch Fabs achieve higher yield, more stable cycle times, and lower hidden scrap costs under the same investment.

Data-Driven Intelligence: Freeing Engineer Focus, Concentrating on Value Judgment

In 12-inch factories, what truly constrains efficiency is often not "computing power", but engineers' attention. GETECH's GMES system, through data-driven and rule/algorithm collaboration, creates a series of intelligent functions, freeing engineers from repetitive work, focusing on core engineering judgment and innovation.

Smart Sampling Strategy: Dynamically adjusts sampling strategies based on process stability, WIP level, Lot attributes, etc., releasing equipment capacity in stable stages, increasing monitoring density in abnormal stages, enhancing yield monitoring sensitivity.

Intelligent Dispatching and Fully Automated Operation: With the help of the IAM intelligent automation management platform, integrating conditions such as Q-Time, contamination level, equipment status, NPW level to achieve "equipment pulling, system decision-making", automatically completing handling, loading/unloading, cleaning and other operations.

Intelligent Exception Monitoring: Through the EMS+AMS event system, unified monitoring, hierarchical alerting, and workflow-driven for key events such as equipment alarms, Q-Time risks, low yield, SPC anomalies, ensuring important events are closed in time.

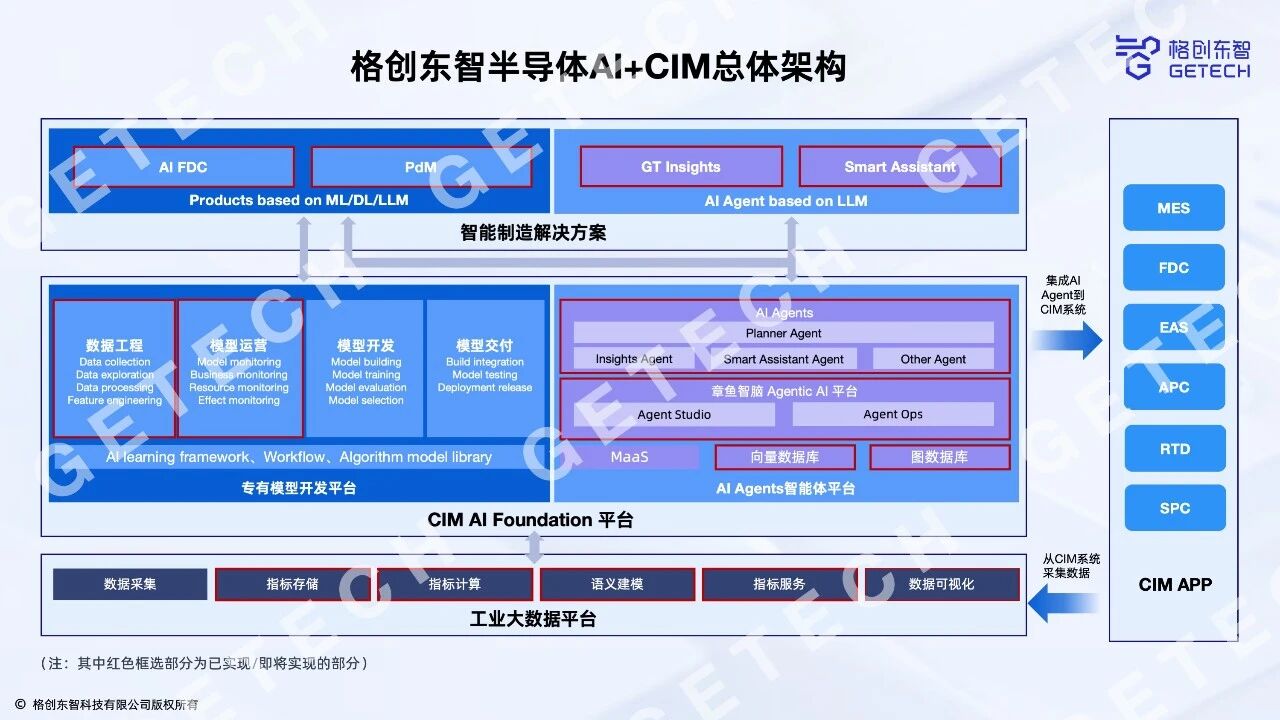

AI/Large Model Collaboration: Relying on GETECH's self-developed industrial big data and large model platform, high-quality process data collected by GMES can link with AI applications like smart work order assistants and equipment maintenance assistants, providing decision support in recipe optimization, abnormal root cause analysis, predictive maintenance, etc.

Building on GMES, Moving Towards the Future of 12-inch Smart Factories

GETECH's 12-inch GMES system, with "fitting business, solving pain points, creating value" as the core, relying on its robust architecture, complete function coverage, deep process integration, and intelligent data application, has become a common choice for many wafer fabs in digital transformation. Whether it's building new advanced process production lines or intelligent upgrades of existing production lines, the GMES system can provide customized solutions, helping every wafer fab build a future-oriented smart factory, gaining a competitive edge in the semiconductor industry, leading the new journey of intelligent manufacturing.